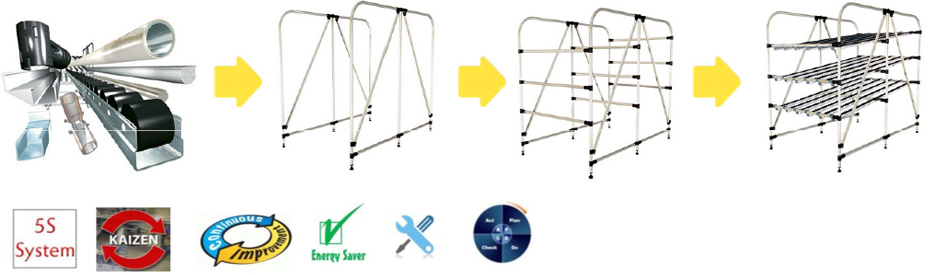

Pipe and Joint System is a FLEXIBLE and DIY system consists of pipe, joint and specialized accessories, assembled in a variety of configurations to serve various function. It is commonly used as storage and handling equipment including rack, shelve, workstation and trolley. We have a wide-range of pipe and joint system, applicable in diverse industries application, including ESD conductivity to remove static electricity, or for “anti-dust” application. It optimizes your production efficiency and space-saving where rack, trolley or working table can be easily formed based on your specific application requirement or your desired design.

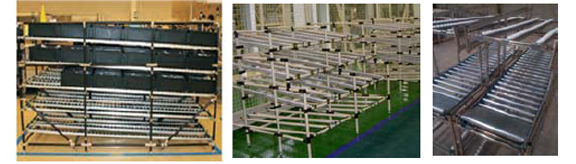

Flow rack can be customized and personalized to suit your production Line, to supply the material to operator in a most cost & effective solution

With the fast‐moving invenory control, Pipe and Joint Storage System able to provide flexible storage FIFO solution to fit any sized box, container.

By designing custom work stations to bring components and tools within immediate reach of operators, modular design able us to change to suit for fast‐changing production line.

Ease to move WIP product o next assemblty point. Able to carry any size or shape of product designing with your load & special handling requirement

With the creativity, and the combination of our pipe and connectors , the application is limitless possibility.